Tech Details

| WAB ECO 2080 | WAB ECO 2580 | WAB ECO 3080 | WAB ECO 30120 | WAB ECO 30160 | WAB ECO 30200 | WAB ECO 37160 | WAB ECO 37200 | |

| Max. Pressing capacity to | 80 | 80 | 80 | 120 | 160 | 200 | 160 | 200 |

| Chamfer length, mm | 2100 | 2600 | 3100 | 3100 | 3100 | 3100 | 3760 | 3760 |

| Clear distance between columns | 1700 | 2200 | 2600 | 2600 | 2600 | 2600 | 3250 | 3250 |

| Ram stroke | 160 | 160 | 160 | 160 | 160 | 160 | 160 | 160 |

| Overhang | 380 | 380 | 380 | 385 | 395 | 415 | 395 | 415 |

| Installation height mm | 250 | 250 | 250 | 250 | 250 | 250 | 250 | 250 |

| Table height above the corridor | 900 | 900 | 900 | 900 | 900 | 900 | 900 | 900 |

| overall length | 3250 | 3750 | 4360 | 4250 | 4250 | 4450 | 4910 | 5110 |

| Total height | 2400 | 2400 | 2400 | 2500 | 2550 | 2650 | 2650 | 2650 |

| Overall width | 1950 | 1950 | 1950 | 1900 | 1900 | 2050 | 1900 | 2050 |

| Forward speed mm / sec. | 90 | 90 | 90 | 90 | 90 | 100 | 90 | 100 |

| Pressing speed mm / sec | 7,5 | 7,5 | 7,5 | 7,5 | 6,1 | 7 | 6,1 | 7 |

| Reverse speed | 60 | 60 | 60 | 65 | 60 | 75 | 60 | 75 |

| main engine | 5,5 | 5,5 | 5,5 | 7,5 | 7,5 | 11 | 7,5 | 11 |

| Adjustable backgauge X-axis | 800 | 800 | 800 | 800 | 800 | 800 | 800 | 800 |

| Weight kg | 4857 | 5220 | 5790 | 6910 | 7520 | 9310 | 8510 | 10440 |

| WAB ECO 40120 | WAB ECO 40160 | WAB ECO 40200 | ||||||

| Max. Pressing capacity to | 120 | 160 | 200 | |||||

| Chamfer length, mm | 4100 | 4100 | 4100 | |||||

| Clear distance between columns | 3600 | 3600 | 3600 | |||||

| Ram stroke | 160 | 160 | 180 | |||||

| Overhang | 385 | 395 | 415 | |||||

| Installation height mm | 250 | 250 | 250 | |||||

| Table height above the corridor | 900 | 900 | 900 | |||||

| overall length | 5050 | 5050 | 5050 | |||||

| Total height | 2500 | 2500 | 2500 | |||||

| Overall width | 1900 | 1900 | 2050 | |||||

| Forward speed mm / sec. | 90 | 90 | 100 | |||||

| Pressing speed mm / sec | 7,5 | 6,1 | 7 | |||||

| Reverse speed | 65 | 60 | 75 | |||||

| main engine | 7,5 | 7,5 | 11 | |||||

| Adjustable backgauge X-axis | 800 | 800 | 800 | |||||

| Weight kg | 8640 | 9210 | 11290 |

Description

HIGHLIGHTS

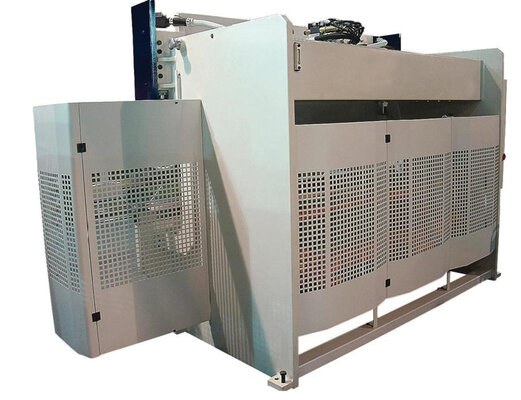

- Stable welded construction

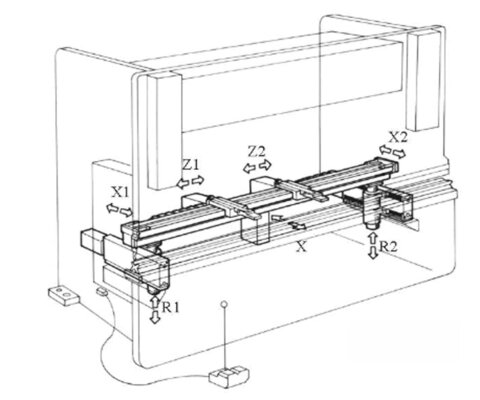

- 3 - 8 axes control

- Extensive program

- The printing cylinders are made of high quality

high quality steel and precisely honed

with Heidenhain direct measuring system

- Hardened, chrome-plated and precision ground

Pistons

- Hardened and ground ram guides

- HOERBIGER hydraulic blocks

- Siemens electrics

- Standard table with T-slots

- Swiveling control panel

- Multifunctional foot switch (CE standard)

with all the necessary pushbuttons

- Lateral protective grille with safety switch

- Front protection with light barrier -

Leuze system

- Protection at the rear with light barrier -

Leuze system

- 1-axis back gauge with Mitsubishi

Servo motor and 2 stops

- Adjustment of the stop finger with

Precision bearings with an accuracy

of ± 0.01 mm

- Upper tool quick clamping with

Promecam / Amada eccentric lever system

- Upper tool rolls P97.85 R 08

-Lower tool rolleri (die) M460R

Control Cybelec CybTouch 12 PS-2D

-12 "color TFT

-2 D representation of the bending part

- Calculation functions:

- pressing force - depth

- crowning

- Angle backgauge correction

-Automatic function

-Single block programming for creating the finished part

-USB interface

-2D offline software for external programming